In the ever-evolving landscape of the beverage industry, where taste, appearance, and shelf life are paramount, technological advancements continue to play a pivotal role in meeting consumer demands. One such technological innovation that has garnered attention is deaerating systems. These systems have transformed the way beverages are produced, ensuring optimal quality, flavor, and longevity. In this blog, we will delve into the significance of deaerating systems in the beverage industry and their impact on product excellence.

Understanding Deaeration: The Basics

Deaeration is a process that involves removing dissolved gases, primarily oxygen, from liquids. Oxygen, although essential for human life, can be detrimental to the quality and shelf life of beverages. When present in liquids, oxygen can lead to oxidative reactions, altering the flavor, color, and aroma of the product. Additionally, oxygen can contribute to microbial growth and spoilage, resulting in a shorter shelf life.

Deaerating systems, also known as oxygen removal systems, tackle this challenge by effectively reducing the oxygen content in beverages. These systems are particularly crucial for carbonated beverages, fruit juices, wine, beer, and other liquid products that are susceptible to oxidation.

The Role of Deaerating Systems in the Beverage Industry

- Enhanced Flavor Profile: Oxygen can interact with various compounds in beverages, leading to off-flavors and an overall degradation of taste. Deaerating systems help preserve the natural flavor profile of beverages, ensuring that consumers experience the product as intended by the manufacturer.

- Extended Shelf Life: By reducing the oxygen content, deaerating systems extend the shelf life of beverages. This not only reduces waste but also allows manufacturers to reach broader markets and maintain consistent product quality over time.

- Improved Appearance: Oxygen-induced reactions can alter the color and visual appeal of beverages. Deaeration helps retain the vibrant colors and clarity that are essential for attracting consumers and conveying freshness.

- Minimized Risk of Contamination: Lower oxygen levels inhibit the growth of aerobic microorganisms, reducing the risk of spoilage and contamination. This is especially important for non-pasteurized and minimally processed beverages.

- Consistency and Control: Deaerating systems offer precise control over the oxygen levels in beverages, ensuring batch-to-batch consistency. This level of control is crucial for maintaining a strong brand reputation and meeting consumer expectations.

Types of Deaerating Systems

There are several methods employed by the beverage industry to remove oxygen from liquids:

- Vacuum Deaeration: Vacuum systems create a vacuum in a closed vessel containing the liquid. As the pressure drops, the dissolved gases are released as bubbles, which are then removed. Vacuum deaeration is commonly used for both carbonated and non-carbonated beverages.

- Membrane Deaeration: Membrane systems use semipermeable membranes to selectively allow gases to pass through while retaining the liquid. This method is effective for removing dissolved gases, including oxygen, without altering the product’s composition.

Deaerating systems have emerged as an indispensable asset to the beverage industry, revolutionizing the way products are processed, packaged, and preserved. By mitigating the harmful effects of oxygen, these systems ensure that consumers enjoy beverages with superior flavor, extended shelf life, and uncompromised quality. As technological advancements continue to refine these systems, the beverage industry stands to benefit from enhanced production practices and delighted customers.

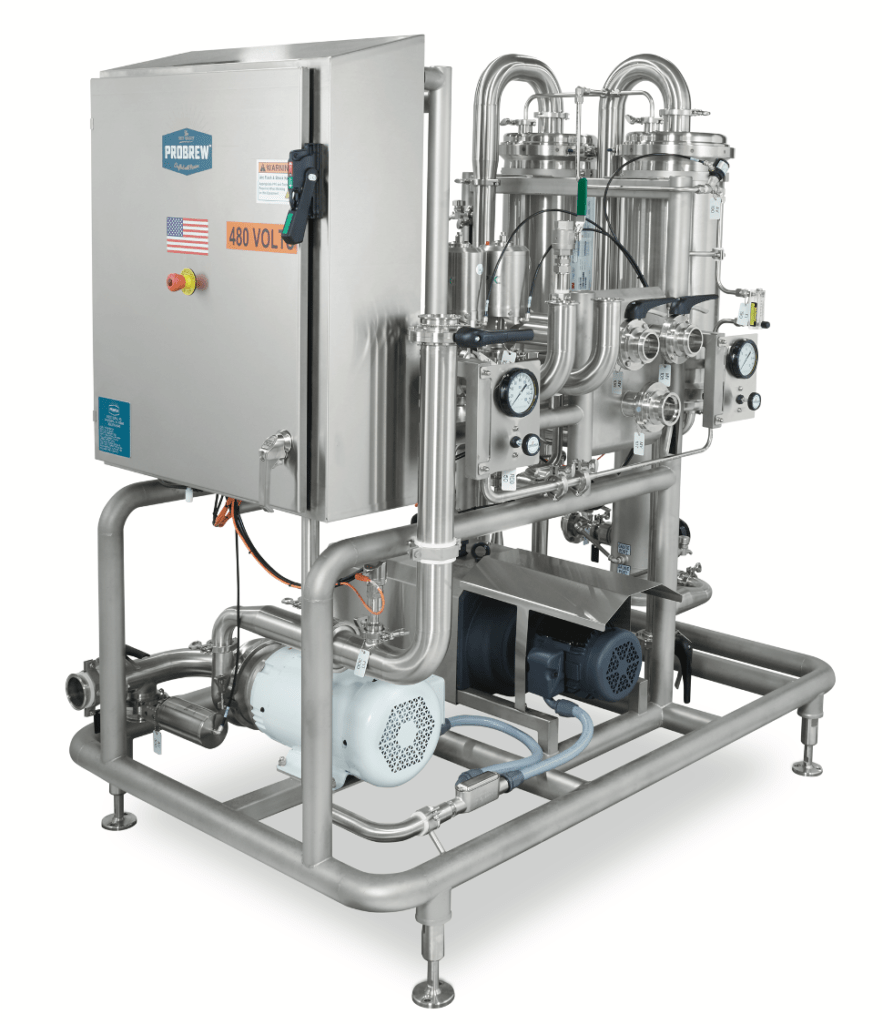

How TechniBlend’s Advanced Systems Empower Beverage Producers

In the dynamic landscape of the beverage industry, where taste, freshness, and shelf-life reign supreme, innovation plays a pivotal role in ensuring consumer satisfaction. TechniBlend, a trailblazing company in the field of beverage processing technology, has emerged as a game-changer with its state-of-the-art beverage deaeration solutions. As a leader in the industry, we at TechniBlend address the crucial challenge of oxygen removal from beverages, enhancing flavor, extending shelf life, and preserving product integrity.

Advancing Beverage Deaeration Technology

TechniBlend’s expertise lies in crafting advanced beverage deaeration systems that cater to the diverse needs of the industry. Their cutting-edge solutions employ a range of innovative techniques, such as vacuum deaeration and membrane deaeration, to effectively eliminate dissolved gases like oxygen from liquids. This precision ensures that beverages maintain their intended flavors, colors, and aromas, resulting in an elevated sensory experience for consumers.

Benefits Beyond Expectations

With TechniBlend’s beverage deaeration systems, beverage manufacturers can reap a multitude of benefits. The removal of oxygen translates into enhanced product stability, extended shelf life, and reduced susceptibility to spoilage, allowing manufacturers to reach wider markets and reduce wastage. Moreover, these systems empower manufacturers with greater control over their production processes, ensuring consistent product quality and reinforcing brand reputation.

In a world where consumers demand nothing less than the best, TechniBlend’s commitment to pushing the boundaries of beverage deaeration technology is evident. By revolutionizing the way dissolved gases are removed from beverages, TechniBlend paves the way for a future where beverage quality and consumer satisfaction remain at the forefront. To learn more about TechniBlend’s groundbreaking beverage deaeration solutions and how they are shaping the beverage industry, visit their website here.