By Tom Lex, Head of Engineering at TechniBlend and ProBrew

The beverage industry is a dynamic and ever-evolving sector that caters to the diverse tastes and preferences of consumers worldwide. From soft drinks to alcoholic beverages and everything in between, efficient and precise blending and batching systems are crucial for meeting the demands of this fast-paced industry. In this blog, we will explore the significance of blending and batching systems in the beverage industry and delve into their role in optimizing production processes.

I. The Importance of Blending and Batching Systems:

Blending and batching systems play a pivotal role in the beverage industry, where consistency and quality are paramount. These systems enable manufacturers to combine various ingredients in precise quantities, ensuring that each batch of beverage meets the desired flavor, texture, and aroma profiles. By employing automated blending and batching systems, companies can achieve consistency across multiple production runs, guaranteeing a standardized product that consumers can trust.

II. Enhancing Efficiency with Automation:

Accuracy and Precision: Automated blending and batching systems eliminate the risk of human error, ensuring precise measurement and mixing of ingredients. This not only maintains product consistency but also reduces waste, as it minimizes the chances of over-pouring or under-pouring ingredients.

Time and Cost Savings: Traditional manual blending and batching processes are time-consuming and labor-intensive. Automation streamlines these operations, significantly reducing production time and labor costs. Automated systems can also handle larger volumes, allowing manufacturers to meet high demand without compromising on quality.

Recipe Management: Advanced blending and batching systems offer recipe management capabilities, enabling manufacturers to store and retrieve multiple recipes with ease. This flexibility allows for quick adjustments and the ability to replicate successful formulas consistently.

III. Flexibility and Customization:

Tailored Formulations: Blending and batching systems empower beverage manufacturers to create unique and customized formulations. With precise control over ingredient quantities and proportions, companies can experiment with new flavors, adjust existing recipes, and respond to evolving consumer preferences.

Ingredient Compatibility: Certain beverages require specific blending and batching processes to ensure proper ingredient compatibility. Automated systems can handle complex mixtures and incorporate ingredients with varying viscosities, densities, and particle sizes, ensuring a homogeneous blend every time.

IV. Quality Control and Traceability:

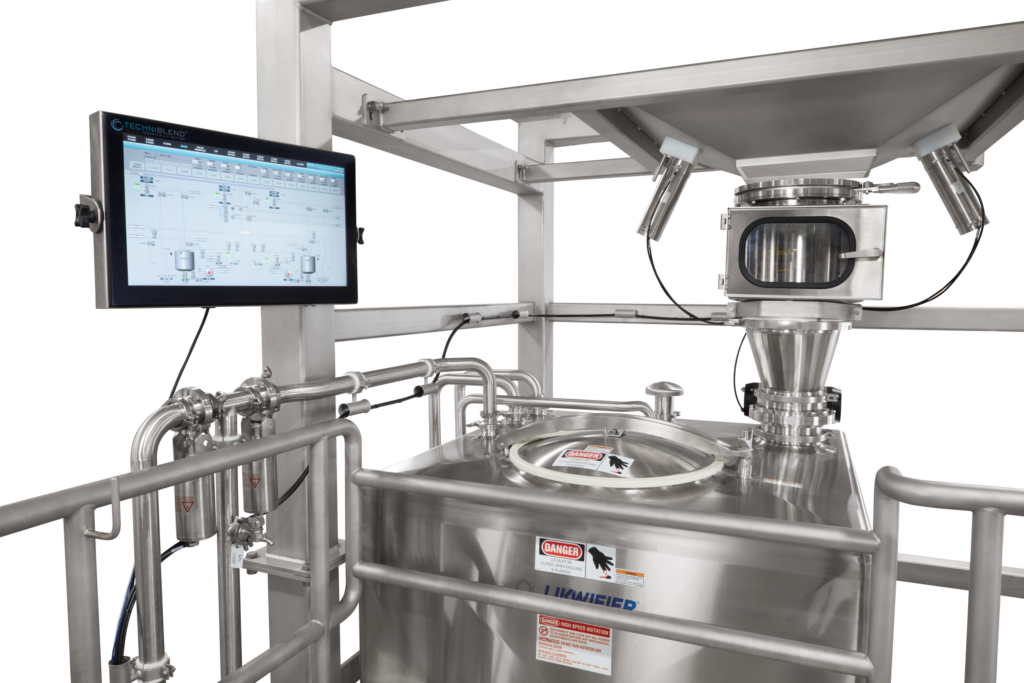

Quality Assurance: Blending and batching systems support rigorous quality control measures by providing real-time monitoring of production processes. Manufacturers can track critical parameters such as temperature, Brix, Titratable Acidity, ABV, pH levels, and mixing time, enabling prompt adjustments, and ensuring the final product meets quality standards.

Traceability: In the event of a product recall or quality issue, traceability is of utmost importance. Advanced blending and batching systems allow for accurate tracking and documentation of raw materials, batch numbers, and production data, facilitating efficient root-cause analysis and targeted recalls, if necessary.

How TechniBlend Stands Above the Rest

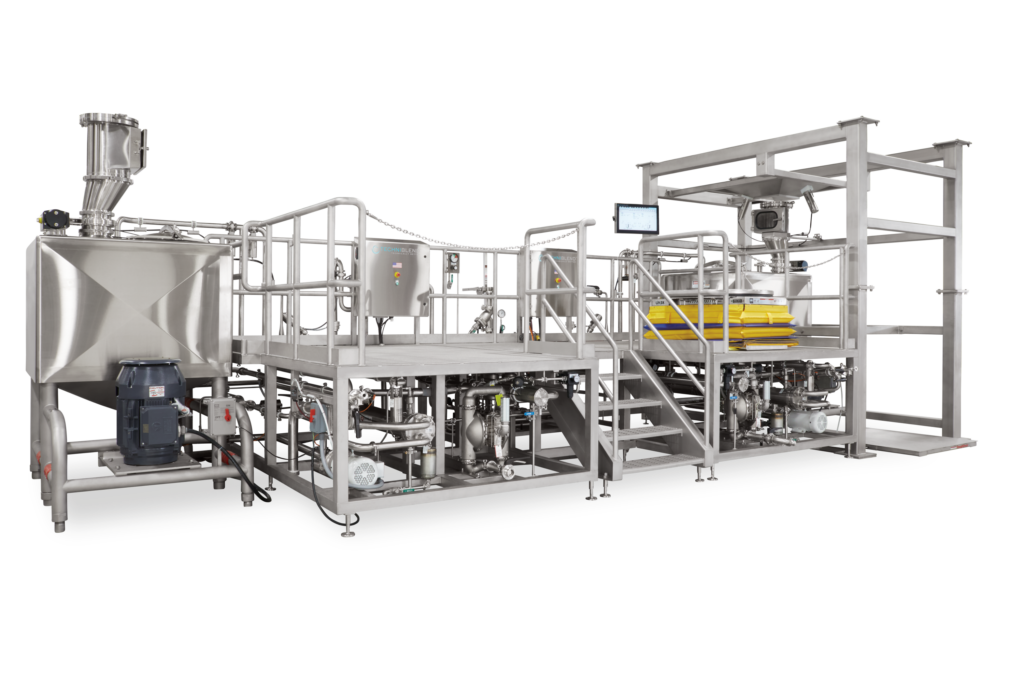

TechniBlend’s series of blending and batching systems harnesses all the key benefits laid out in this article into a customizable offering. Our series of systems utilizes automation wherever specified, allowing beverage producers of any industry to enjoy product consistency, regardless of flavor, texture, and aroma profiles. The increased management of the product also allows for more control over carbonation and alcohol levels.

TechniBlend goes beyond just blending and batching systems as well, offering fully integrated Clean-In-Place systems that efficiently remove any lingering product from a previous production run. In addition, TechniBlend offers deaeration and pasteurization systems that allow beverage producers to expand their product offering while still focusing on their flagship products.

For more information on any TechniBlend system, please visit techniblend.com, email contact@techniblend.com or give us a call at 262-484-4090.

About the Author

Tom Lex, Head of Engineering at TechniBlend and ProBrew

Tom Lex heads an engineering team that has over 150+ years of combined beverage processing experience. He has overseen some of the most incredible projects that TechniBlend has undertaken and has repeatedly gone above and beyond for our customers.